- HOME

- PRODUCTS

- Arm Protection (119)

- Cold Stress (1)

- Critical Environment (170)

- Electrical Safety (133)

- Emergency Responder (37)

- Ergonomics (12)

- Eye Protection (356)

- First Aid (17)

- Hand Protection (1447)

- Head Protection (103)

- Hearing Protection (49)

- Heat Stress (37)

- Protective Clothing (454)

- Respiratory Safety (44)

- Warning Beacons (28)

- BRANDS

- CHANNELS

- Sales Tools

- NEWS, ARTICLES & EVENTS

- Log in or Sign Up

- PRODUCTS

- /// Hand Protection

- /// Hand Protection

- Chemical Resistant Gloves

- Cold Protection Gloves

- Cut Resistant Gloves

- Disposable Gloves

- Fabric Work Gloves

- General Purpose Gloves - Coated

- General Purpose Gloves - Uncoated

- Heat Protection Gloves

- High Performance Gloves

- Leather Drivers Gloves

- Leather Palm Gloves

- Parade & Uniform Gloves

- /// Head Protection

- /// Eye Protection

- /// Hearing Protection

- /// Respiratory Safety

- /// Protective Clothing

- /// Arm Protection

- /// Heat Stress

- /// Warning Beacons

- /// Cold Stress

- /// Ergonomics

- /// First Aid

- /// Welding Protection

- /// Controlled Environment

- /// Electrical Safety

- /// Emergency Responder

- /// Hand Protection

- BRANDS

- CHANNELS

- SALES TOOLS

Hidden Risks on the Job Site

Nearly five million workers currently make up the American construction industry. That includes laborers, carpenters, trade and extraction workers, site managers and others. While it may not be apparent from a distance, there are lots of different jobs and tasks occurring simultaneously on a job site – all with their own associated risks. It is important that PPE be selected based on its ability to protect against these identified risks. Each job usually has its own set of obvious hazards and risks, but what about the less obvious ones? Let’s highlight a few hidden risks that exist on a construction job site.

.jpg?width=485&name=iStock-1182207424%20(3).jpg)

LESS OBVIOUS JOB SITE HAZARDS

UV RAYS

The sun affects construction workers year-round and has become a silent danger even in the cooler months. Cooling PPE and consistent hydration are essential when combating heat exhaustion however these remedies alone do not put the negative impacts of the sun’s UV rays to rest. Overexposure to UV rays can lead to severe burning of the skin and even skin cancer. This should urge safety managers to assure the PPE their workers are using is providing the right level of protection against the sun’s rays as well as performing as needed in order to truly invest in the long-term health of their employees.

![]()

UV rays have the ability to penetrate through clothing and onto the skin depending on the color and construction of the materials used. That is why PIP® offers a line of UV protective clothing complete with 50+ UPF, the highest rating of UV protection available for ANSI compliant garments.

Z87+ Eyewear provides impact protection and side protection, but what about UV ray protection? Eyes, just like the skin, need protection even on cloudy days. Shaded lenses do a great job of protecting the eyes from UV rays and glare, but many dismiss the efficiency of clear lenses. Clear lenses provide protection from 99.9% of UV rays. This is true for impact and non-impact rated eyewear which is useful for workers enduring UV rays from the sun and or UV radiation from a welding/metal working application on the job site.

Z87+ Eyewear provides impact protection and side protection, but what about UV ray protection? Eyes, just like the skin, need protection even on cloudy days. Shaded lenses do a great job of protecting the eyes from UV rays and glare, but many dismiss the efficiency of clear lenses. Clear lenses provide protection from 99.9% of UV rays. This is true for impact and non-impact rated eyewear which is useful for workers enduring UV rays from the sun and or UV radiation from a welding/metal working application on the job site.

![]()

A hard hat that can withstand the effects of the sun while also delivering high performing impact resistance is important for a construction worker. PIP® offers an extensive line of hard hats (both vented and non-vented) constructed with HDPE and polycarbonate materials that inherently retain their color and structural integrity with prolonged exposure to sunlight. These materials along with UV resistant features such as extended full brims and compatibility with hi-vis shading accessories minimize exposed areas of skin on the head, neck and parts of the shoulders making them less susceptible to sun damage.

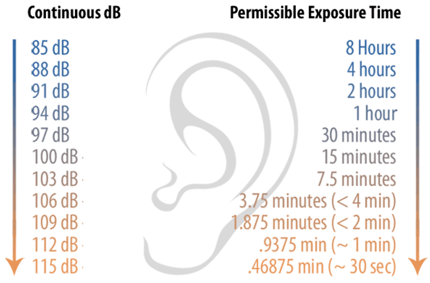

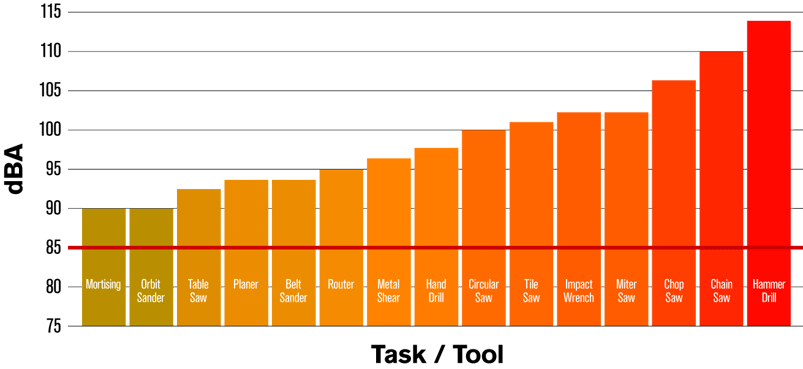

HARMFUL NOISE

It is a known fact that construction workers ignore the risk of elongated exposure to noise on the job site. According to NIOSH, about 51% of all construction workers are exposed to hazardous noise throughout the workday, with 31% of those workers reportedly not wearing hearing protection. The average continuous noise level of a construction site can exceed 90 dBA, which only allows for roughly two hours of permissible exposure time without hearing protection to avoid permanent hearing damage.

Hybrid hearing protection provides a convenient way for construction workers to apply hearing protection. Traditional ear plugs involve the removal of gloves to roll and apply the plug or worse, the application an ear plug with soiled gloves resulting in ear infections and hygienic issues. This alone makes hybrid hearing protection an optimal solution for both ear canal health and time management on the job site when considering an alternative to earmuffs or traditional ear plugs.

![]() PIP’s EZ-Twist™ ear plugs (available in corded and non-corded styles) eliminate the need to roll the ear plug before fitting due to their unique design. With a convenient handling stem located at the base of the foam, workers can gently press and twist the plug into their ear canal without the need of both hands. This is an ideal solution for unsanitary work environments where users’ hands or their hand protection is soiled.

PIP’s EZ-Twist™ ear plugs (available in corded and non-corded styles) eliminate the need to roll the ear plug before fitting due to their unique design. With a convenient handling stem located at the base of the foam, workers can gently press and twist the plug into their ear canal without the need of both hands. This is an ideal solution for unsanitary work environments where users’ hands or their hand protection is soiled.

FALLING OBJECTS

Construction workers often find themselves working with tools on scaffolding when working on infrastructure and commercial sites. Even residential construction requires working at heights, making dropped objects a threat to workers below. Falling object prevention is key when considering the safety of ground-level workers. A tool weighing just two pounds has resulted in numerous cases of severe head trauma and even death in some instances when dropped onto the head of another worker from 15 feet or higher. That is why the ANSI/ISEA 121 standard was created; to bring a consistent set of guidelines to dropped object prevention and to eliminate the use of makeshift tethering solutions such as duct tape and fabric/string. The standard requires that the rated tool attachment be greater than or equal to the weight of the tool. And that the tether weight limit and the anchor weight limit be equal to or greater than the weight allowance of the tool attachment. OSHA does require employers to address dropped object hazards, which will now be easier than ever to adhere to given the growing popularity of drop prevention and fall protection PPE.

![]() PIP® tool lanyards and other drop prevention accessories are designed with high performing features such as reinforced shock cords and barrel lock carabiners that permit a durable and secure attachment to tools when on the job site. It not only provides a protective measure but a preventative measure as well.

PIP® tool lanyards and other drop prevention accessories are designed with high performing features such as reinforced shock cords and barrel lock carabiners that permit a durable and secure attachment to tools when on the job site. It not only provides a protective measure but a preventative measure as well.

BOUNDARY VISIBILITY

Sure, making a worker visible on a job site is crucial, but what about the boundaries and work zones of a job site? Construction sites, with high levels of activity, mean workers need to be alert at all times to avoid accidents. In the course of a normal workday they’re exposed to on-site deliveries, loading and unloading of materials, cranes, cement trucks coming and going and other activity – meaning workers need to be aware of potential hazards at all times to stay safe. 25% of accidents occur in the evening despite the fact that less than 9% of the workforce is on duty and more than half of fatalities caused by run-overs or back-overs involve construction vehicles. Such collisions have been attributed to limited visibility around equipment, with statistics concluding that 29% of workers were cleaning or repairing, 28% walking along the road and 18% directing traffic.

![]()

Eflare® warning beacons provide durability and visibility on any job site. Unlike traditional flares, Eflare® products are intrinsically safe and water resistant. To minimize the risk of worksite accidents and to maximize worker awareness, using intensely bright Eflare® beacons will ensure boundary awareness and worker safety. Simply place Eflare® beacons around vehicle paths, at unloading areas or no-go zones or having workers clip them on their tool belt dramatically increases awareness.

INNOVATION LEADING THE WAY

Often, construction is associated with “run of the mill PPE.” However, true construction and safety professionals understand the complexity behind keeping the men and women of construction safe. PIP® recognizes this and works tirelessly to bring new and innovate safety solutions to the construction market. Just another way that PIP® is Bring the Best of the World to You®.

Click HERE to contact your local PIP® rep today or comment below!

Construction Safety Week 2021: Trending Safety Solutions In Construction

According to OSHA, the continuously evolving construction industry accounts for one in five...Construction Safety Week 2023: Trending Safety Solutions In Construction

According to OSHA, the continuously evolving construction industry accounts for one in five...ARC Flash Hoods: Close the Gap Between Comfort and Compliance

When working in high voltage environments, workers must protect themselves against ARC flash...Proposition 65 | Privacy Policy | Contact Us | Full Site

© 2012-2026Protective Industrial Products, Inc. All rights reserved.